Membrane Bioreactor Plus (MBR+) system

Fig. MBR+ System

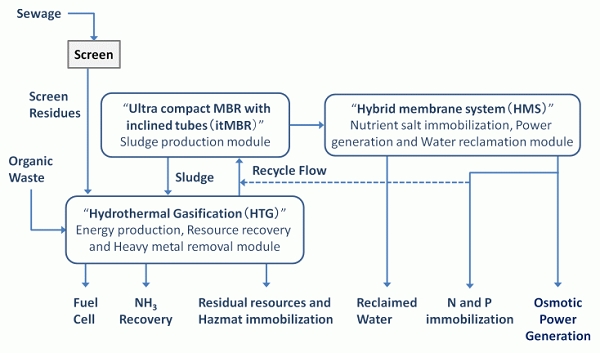

ReproMise (Resources Productive Membrane Integral System for Sewage) is proposed in this study, where a MBR based sewage treatment system “MBR+ system” is to be developed. The system is targeting the renovation of energy consuming municipal wastewater treatment plants (WTPs) with capacity of 100,000 m3/day to energy productive ‘biomass water plants (BWPs)’.

The MBR+ system consists of three modules: Ultra compact MBR with inclined tubes (itMBR), hybrid membrane system (HMS) and hydrothermal gasification (HTG).

Inclined tube MBR (it-MBR)

Fig. itMBR

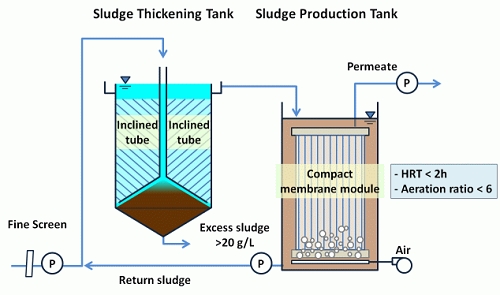

This module, called “itMBR” (“it” denotes “in-line thickener” as function and “inclined tube” as device), consists of two tanks: a sludge thickening tank (STT) installed with inclined tubes and a sludge production tank (SPT) with submerged membrane.

Inclined tubes in STT enhance settling of sludge and accumulate most of the sludge returned from SPT. This functions to keep the MLSS concentration in SPT in a suitable range, reducing the burden on membrane filtration. Accumulated sludge in STT is recovered as a biomass resource.

The primary goal of development is to specialize its function in the production of sludge biomass. A pilot reactor has been being operated under 2 h of hydraulic retention time (HRT) in SPT with receiving real wastewater after passing grit chamber. This short HRT and high loading operation leads to maintaining high sludge production rate with minimizing self decay, in addition to achieving a ultra-compact process. Furthermore, suppression of nitrification is also the main purpose. Leaving the management of nitrogen to the following module (HMS), this module aims to escape from the traditional biological nitrification-denitrification process.

Thus, energy consumption is thoroughly reduced. An ultra-compact, flat sheet type-hollow fiber membrane, which is under development, is supposed to be used in this module.

Hybrid Membrane System (HMS)

Fig. Hybrid Membrane System (HMS)

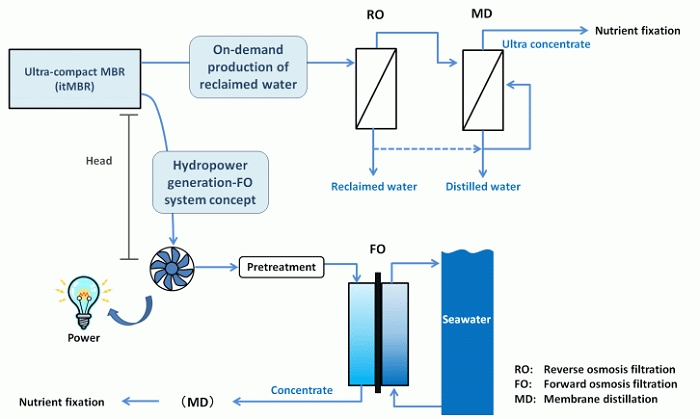

The primary function is to concentrate and fix nutrients in the effluent from the sludge production module (itMBR).

As Hybrid Membrane System (HMS), here are assumed various combinations of membrane technologies. The center of the development is utilization of Forward Osmosis (FO). By exploiting the chemical potential of seawater, FO realizes thorough reduction of energy consumption, ideally no external energy input for the nutrient concentration process.

As a concept, head difference ahead of FO can be made to generate hydropower as well. Alternatively, upon a demand for water reuse, Reverse Osmosis (RO) can be used for simultaneous production of reclaimed water. Membrane distillation (MD) also can be used to achieve ultra-concentration of nutrients and reduction of the amount of brine after FO/RO.

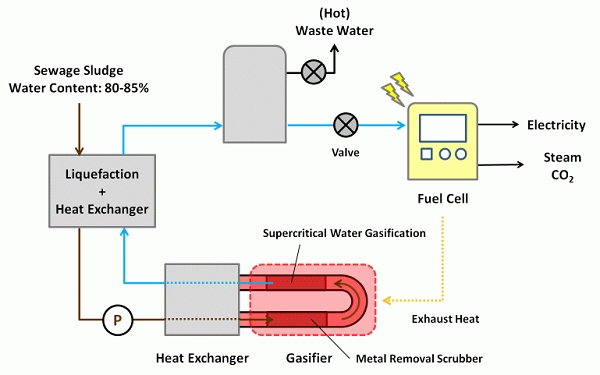

SCWG system

Fig. SCWG system

Produced biomass via itMBR is converted to energy by hydrothermal gasification (HTG) module.

Utilizing supercritical water as a medium, the sludge can be converted to hydrogen rich gas under the gasification efficiency of >90 %. The HTG is also expected to immobilize residual resources and hazardous substances at the same time.

In this study, a continuous supercritical waster gasification (SCWG) system assembled with two pretreatment processes, subcritical water liquefaction and metal removal scrubber, is proposed. The former pretreatment is adopted as a pretreatment to attain stable delivery of the feedstock, whereas the latter pretreatment aims to remove inorganic metals which are likely to provoke plugging and catalyst deactivation during the SCWG reaction.

Finally, a brief calculation on energy balance and cost analysis on the system installed to a municipal WWTP with a conventional activated sludge process is demonstrated.

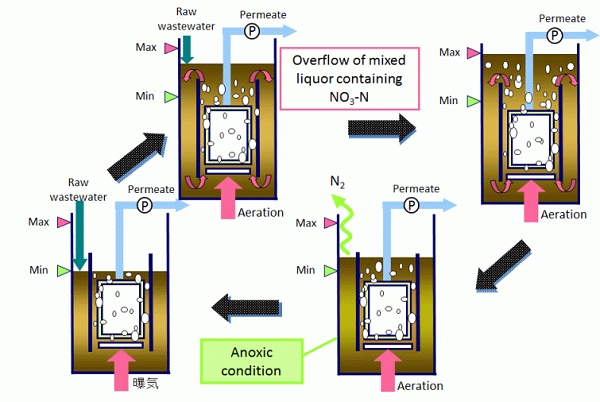

Baffled Membrane Bioreactor (BMBR)

Fig. BMBR operation

In this study, optimization of operating conditions of baffled membrane bioreactor (BMBR) will be conducted. In this MBR, a baffle is inserted in an MBR tank and water level is allowed to move across the upper end of the inserted baffle. As a result, aerobic and anoxic conditions are alternatively created in the outer zone.

We previously reported that both nitrogen and phosphorus can be removed effectively by this MBR under appropriate operating conditions. In this research period, we develop a new air diffuser which allows us to operate an MBR with lower aeration rate (i.e., lower operating cost). The phosphorus removal mechanism in BMBR is also investigated to establish a design concept of this MBR. In addition, to establish a strategy for preventing membrane fouling (the universal problem in MBRs), we investigate fouling mechanisms in MBR in detail.